Fluorosilicone Hose Manufacturer

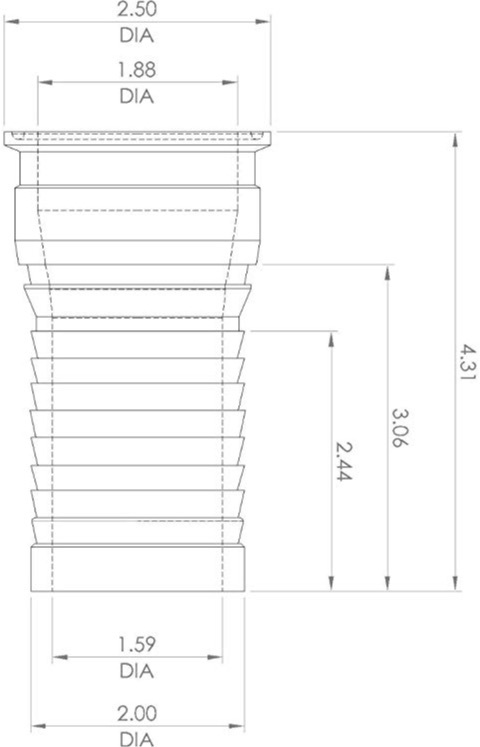

Fluorosilicone combines most of the attributes of silicone with resistance to petroleum oils and hydrocarbon fuel

This elastomer shows significantly better chemical resistance than standard Silicone especially in hydrocarbons, aromatic mineral oils, fuel and low molecular aromatic hydrocarbons e.g. Benzene and Toluene.

Benefits of Fluorosilicone Rubber

As a fluorosilicone hose manufacturer, we use FVMQ due to its ability to withstand heat at extreme temperatures. It has good electrical properties and excellent resistance to weather, ozone and UV rays. It also has excellent compression set resistance and is very clean, with low odor and low taste.

The temperature range is between -50 °C/-58 °F and +175 °C/+347 °F (temporary up to +200 °C/+392 °F). Some formulations will work under high temperature situations up to 225°C giving it excellent thermal stability making it ideal for charge air cooler and turbo hoses.

Low physical strength and abrasion resistance combined with high friction limit some applications for fluorosilicone and it typically has poor friction properties and poor abrasion resistance.

Flurosilicone is an established material within automation hose manufacturing, specifically oil and diesel filler applications where batch sizes can vary. It can be incorporated into the design of any bespoke shaped hose to suit your unique application and to prolong the life expectancy of the hose.

Goodflex’s unique flurosilicone has been specifically formulated with one of the highest fluorine content feasible to provide superior chemical resistance to standard flurosilicones.

The molecular structure gives improved gas impermeability and it also gives of the widest temperature ranges available for an oil resistant grade elastomer.

FVMQ has a good heat resistance at extreme temperatures and very good low temperature flexibility

It has good electrical properties and excellent resistance to weather, ozone and UV rays

Excellent compression set resistance and is very clean, with low odor and low taste.

Typically has poor friction properties and poor abrasion resistance.

Flurosilicone is an established material for oil and diesel filler applications

Case Studies

We Work with Leading Companies and High Performance Teams within Engineering and Procurement

Here are some Case Studies of Companies that Goodflex Work with Day to Day