Search Goodflex products by

-

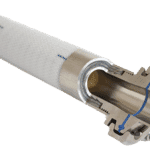

Goodflex supply hoses, mouldings & assemblies to suit your specific requirements

-

Goodflex supply hoses, mouldings & assemblies for a wide range of applications

-

Goodflex has one of the largest ranges of materials available in the UK

-

Goodflex supply hoses, mouldings & assemblies to a diverse range of industries

The Goodflex Way

We are a UK based silicone rubber hoses, mouldings and assemblies supplier that perform for the entire product service life

Goodflex

RAPID

For engineering teams completing rapid prototype and advanced production projects seeking to mitigate risk in the design of hoses, mouldings and assemblies

Goodflex

READY

For procurement teams seeking supply chain partners ready to mitigate risk in their supply chain for hoses, mouldings and assemblies